As one of the most critical operational components of an escalator, the step plays a key role in the overall safety, passenger comfort, and energy efficiency of the entire machine. During operation, the steps form a continuous closed loop with the step chain, cycling through the guide rail system, and enabling smooth passenger transportation through precise mechanical coordination.

As the core component that bears passenger weight and directly participates in motion, escalator steps must possess the following essential characteristics:

High Safety

Lightweight, reducing driving energy consumption

High Rigidity with Minimal Elastic Deformation

Low Operating Noise

Strong Corrosion Resistance, suitable for various installation environments

Easy to Install and Maintain, reducing maintenance difficulty

Cost-Effective and Energy-Efficient, ensuring long-term economic benefits for customers

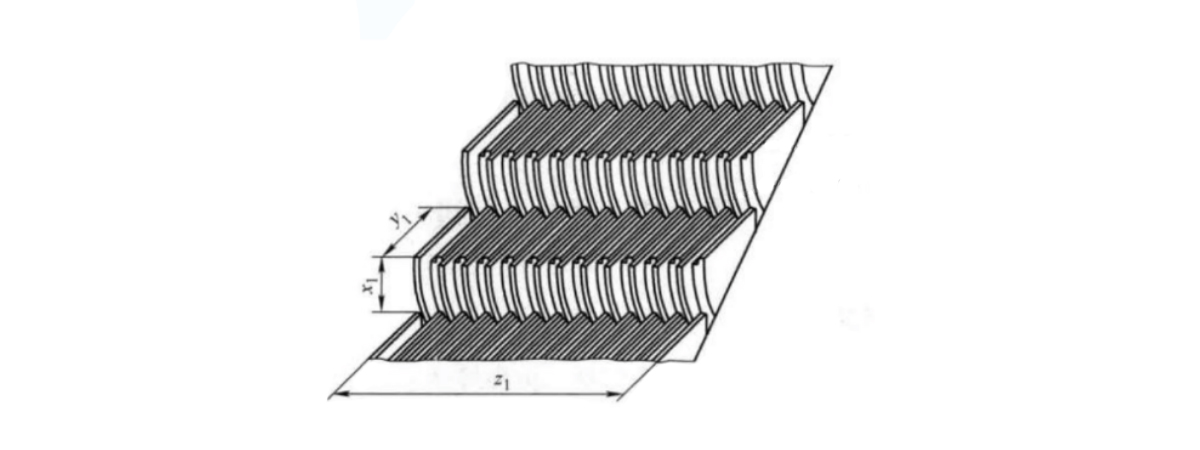

Step Dimensions: Directly Related to Transport Capacity and Passenger Safety

Step Width (z1): 0.58 m – 1.1 m

Common industry sizes: 0.6 m, 0.8 m, 1.0 m

Different widths determine the escalator’s transport capacity, suitable for varying passenger flow scenarios.

Step Height (x1): ≤ 0.24 m

Commonly used: ~0.203 m

Excessive height may inconvenience passengers when stepping on or off, affecting comfort and safety.

Step Depth (y1): ≥ 0.38 m

Commonly used: ~0.405 m

A reasonable depth ensures passenger stability and reduces the risk of missteps.

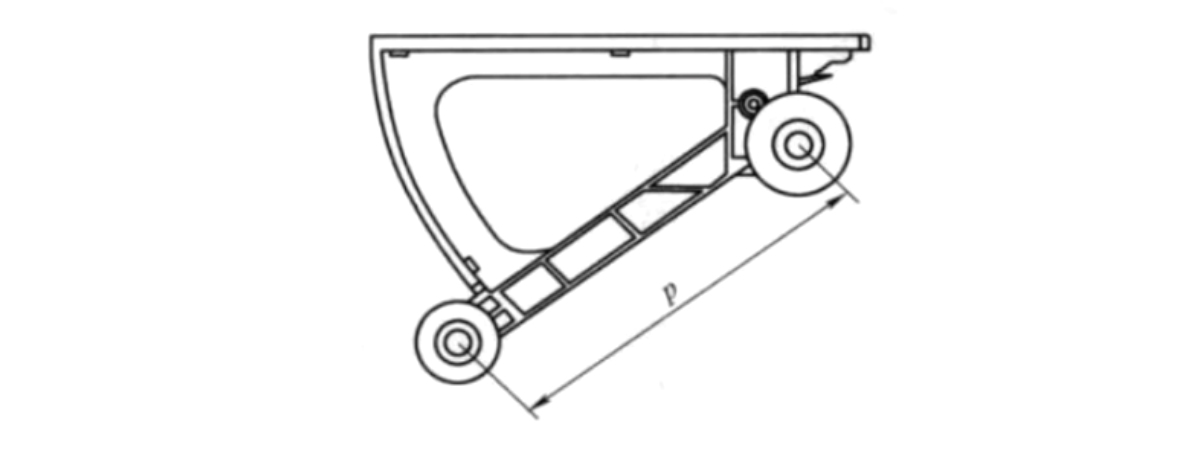

Step Pitch: A Key Structural Parameter

The step pitch refers to the distance between the step chain roller (drive roller) and the step roller (idler roller) and must precisely match the step chain pitch. Designs vary among manufacturers, but the industry standard is approximately 400 mm, ensuring smooth and stable operation.

Material Selection: Balancing Lightweight and High Strength

Aluminum Alloy Steps: Available as integral cast or modular types. The integral type is cast from aluminum alloy in one piece, providing durability and a lightweight design. However, the material, equipment, and mold costs are higher, and the entire step must be replaced if damaged. Mainly suitable for outdoor installations.

Stainless Steel Steps: Made from stamped steel plates (tread, riser, support frame) and fastened with bolts and screws. The edges are finished with yellow plastic trim for safety and aesthetics. Stainless steel steps are more cost-effective and visually appealing but less corrosion-resistant than aluminum alloy steps, mainly used indoors.

With the development of urban public transportation and commercial facilities, escalators have become essential daily transportation devices. The performance and quality of the core component—the step—directly determine passenger safety, comfort, and travel efficiency. We are committed to continuously optimizing step design, providing safe, reliable, and energy-efficient escalator solutions, and contributing to the sustainable development of urban transportation and commercial spaces.

WhatsApp: 8618192988423

E-mail: yqwebsite@eastelevator.cn

Post time: Nov-28-2025