In the elevator safety system, the buffer serves as the final line of defense. It is a crucial safety device designed to protect both passengers and equipment in extreme situations.

When an elevator travels upward or downward and—due to causes such as broken suspension ropes, insufficient traction friction, inadequate braking force, or control system failure—overruns the bottom or top terminal landing, the buffer comes into action.

Much like an automobile’s airbag, the elevator buffer absorbs and dissipates the impact energy, effectively slowing down the car or counterweight to prevent direct collision with the pit floor or the top of the shaft, ensuring the safety of passengers and equipment.

Typically, buffers are installed in the elevator shaft pit, located directly beneath the car and counterweight.

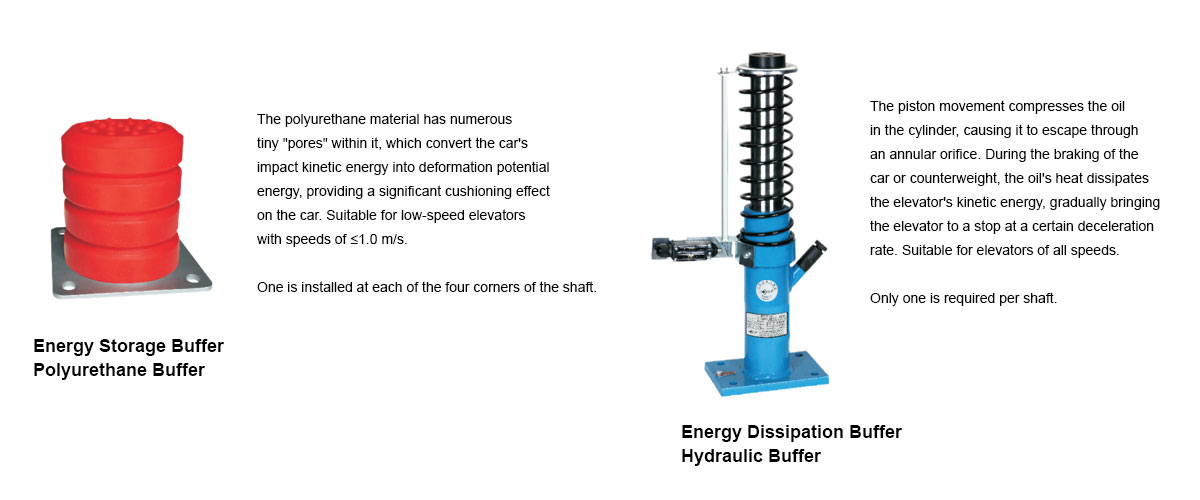

According to elevator speed and energy characteristics, buffers are classified into two main types:

Energy Dissipation Buffers (for medium- and high-speed elevators, represented by hydraulic buffers).

Energy Accumulation Buffers (for low-speed elevators with v ≤ 1.0 m/s, represented by polyurethane buffers).

Hydraulic buffers are widely used for their smooth energy absorption and stable performance, while polyurethane buffers feature compact design and maintenance-free operation, making them ideal for low-speed applications.

With the continuous advancement of elevator technology, modern buffers are being optimized for higher energy absorption efficiency, improved durability, and easier maintenance, ensuring reliable protection under any operating condition.

E-mail: yqwebsite@eastelevator.cn

Post time: Oct-20-2025